机器图片

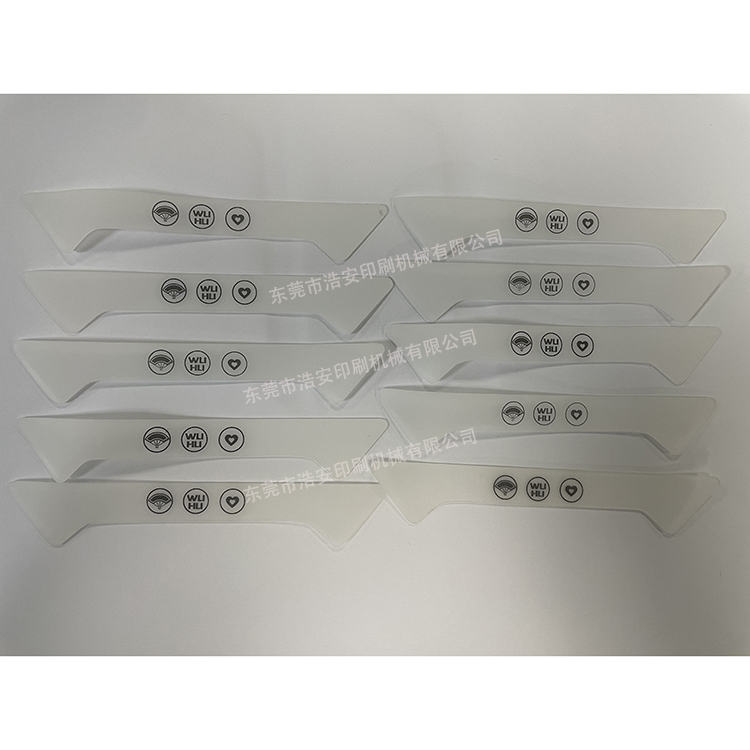

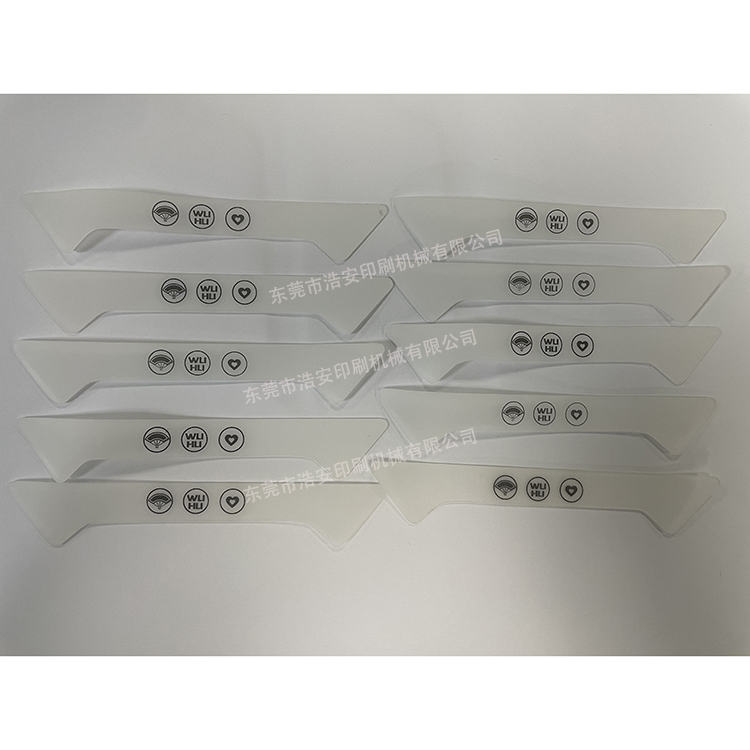

产品图片

该丝印机采用先进的PLC控制,人机界面数字化操作。转盘采凸轮分割器精密驱动,重复精度高,定位精准,速度快。自动下料机械手臂采用步进电机或伺服电机配合精密线性导轨驱动,速度快,稳定性好。此机提供多种功能设定,达到作业数据化、标准化、人性化之完善要求。创新的结构设计,配合顶级伺服传动及导向系统,运行快速,稳定滑顺,定位精准,节省能源,自动下料,节省人工,保证印刷质量。

The wire printing machine adopts advanced PLC control and man-machine interface digital operation. Turtable cam splitter precision drive, high repetition accuracy, accurate positioning, fast speed. Automatic feeding mechanical arm using stepper motor or servo motor with precision linear guide rail drive, fast speed, good stability. This machine provides a variety of function Settings, to meet the operation data, standardization, humanized perfect requirements. Innovative structural design, with top servo transmission and guidance system, fast operation, stable and smooth, accurate positioning, energy saving, automatic feeding, save labor saving, ensure printing quality.

一、 主要参数 key parameter

|

NO

|

项目

project

|

参数

parameter

|

|

1

|

最大印刷面积

Maximum printed area

|

220mmx300mm

|

|

2

|

最大网板尺寸

Maximum mesh board size

|

350mmx500mm

|

|

3

|

套印精度

Inset accuracy

|

±0.03mm

|

|

4

|

工件高度

Creature height

|

0~80mm

|

|

5

|

工作台面面积

Working surface area

|

250mmx350mm

|

|

6

|

转盘直径

Turntable diameter

|

Ø600mm

|

|

7

|

转盘驱动

Turntable drive

|

台湾东元

Taiwan dongyuan

|

|

8

|

凸轮分割器

Cam splitter

|

台湾德士

Taiwan's Dex

|

|

9

|

网版升降驱动

Network version lift drive

|

伺服与气缸选配

Servo and cylinder are optional

|

|

10

|

印刷座架驱动

Printed seat drive

|

步进电机或伺服驱动(选配)

Stepper motor or servo drive (optional)

|

|

11

|

机械手左右驱动

Drive left and right

|

步进电机或伺服驱动(选配)

Stepper motor or servo drive (optional)

|

|

12

|

导向导轨

Guide rail

|

HIWIN

|

|

13

|

夹料机械手上下驱动

The sandwich manipulator drives up and down

|

SMC

|

|

14

|

夹料机械手升降滑动

Clip manipulator lift and slide

|

SMC

|

|

15

|

刮刀气缸

Scrapper cylinder

|

SMC

|

|

16

|

墨刀气缸

Ink knife cylinder

|

SMC

|

|

17

|

换气气缸

Air cylinder

|

SMC

|

|

18

|

工作气压Mpa

working air pressure Mpa

|

0.4~0.6Mpa

|

|

19

|

工作周期

work cycle

|

3S左右

|

|

20

|

定位方式

location mode

|

自动下料(配量身定制的管位)

Automatic feeding (tailored pipe position)

|

|

21

|

机台结构

Machine structure

|

组合而成

Machine structure

|

|

22

|

产能

Machine structure

|

约2200PCS/小时

About 2,200 P C S / h

|

|

23

|

机器重量

machine weight

|

500Kg

|

|

24

|

电源

electrical source

|

220V 50/60Hz1.5KW

|

二、 结构说明 structure specification

1、 丝印机 Screen printing machine

2、 主要性能 main performance

1) 垂直升降设计,采用精密导轨导向快速稳静升降,保养简便,耐长时操作,稳定精度高。

2) 创新结构,强固质轻,节省能源。

3) 左右印刷采用步进电机或伺服电机传动设计,精密导轨导向,运行快速,稳定滑顺,定位精准

4) 换版/装框/定位简易快速,按键式操作大幅减少装夹时间、提升产能。

5) 按键式操作,提供多种功能设定,达到作业数据化、标准化、人性化之完善要求。

6) 设有急停开关、安全复归及自动侦错警示,安全防护周全。

7) 标配烤箱,更快固化油墨,加快效率。

1. Vertical lifting design, the use of precision guide rail guide fast stable and static lifting, simple maintenance, long endurance operation, high stability accuracy.

2. Innovation structure, strong, solid quality and light, energy saving.

3. Left and right printing using stepping motor or servo motor transmission design, precise guide rail guidance, fast operation, stable and smooth, accurate positioning

4. Change / frame / positioning is simple and fast, push-button operation greatly reduces the loading time, improve production capacity.

5. Push-button operation, to provide a variety of function Settings, to achieve the operation data, standardization, humanized perfect requirements.

6. With emergency stop switch, safety return and automatic error detection warning, comprehensive safety protection.

7. Standard oven, faster curing of ink, faster efficiency.

3、结构配置 Structural configuration

|

结构部分

structure division

|

项目

project

|

配件名称

Accessories name

|

配置说明

Configuration instructions

|

|

基本结构

fundamental structure

|

骨架carcase

|

Q235A+优质方通

Q235A + High-quality Fangcom

|

机架及零件

Rack and parts

|

|

封板shrouding

|

优质冷扎板

High quality cold plate

|

四周封板

All around the sealing plate

|

|

其它零部件Other parts

|

铸铝及合金铝

Casting aluminum and alloy aluminum

|

|

|

网版升降

Net version of the lift

|

上下驱动

Up and down drive

|

气缸

cylinder

|

台资

Taiwan-funded

|

|

导 向

fall through

|

导 轨

lead rail

|

HIWIN

|

|

左右系统

Left and right system

|

左右驱动

Left and right drive

|

步进电机或伺服电机(选配)

Stepper motor or servo motor (optional)

|

|

|

导 向

fall through

|

导 轨

lead rail

|

HIWIN

|

|

刮刀系统

Scrapper system

|

刮刀驱动

Scrapper drive

|

气 缸

air cylinder

|

SMC

|

|

导 向

fall through

|

交叉滚子导轨

Cross roller guide rail

|

台资

Taiwan-funded

|

|

机械手系统

arm-and-hand system

|

驱动

drive

|

步进电机或伺服电机(选配)

Stepper motor or servo motor (optional)

|

|

|

导 向

fall through

|

导轨

lead rail

|

HIWIN

|

|

控制系统

operating system

|

控制电路

control circuit

|

PLC

|

三菱

Mitsubishi

|

|

气动控制air-operated controller

|

SMC

|

SMC电磁阀

SMC electromagnetic valve

|

4、机械手结构 Mechanical hand structure

结构说明:

1) 采用步进电机或伺服电机左右驱动机械手臂。

2) 夹料装置升降采用SMC气缸升降。

3) 精密线性导轨导向,稳定滑顺,噪音小。

structure declaration:

1. Use a stepping motor or a servo motor to drive the mechanical arm left and right.

2. SMC cylinder.

3.Precision linear guide rail guide, stable and smooth, low noise.

|

设为首页

设为首页 加入收藏

加入收藏 联系我们

联系我们 您现在的位置:

您现在的位置: