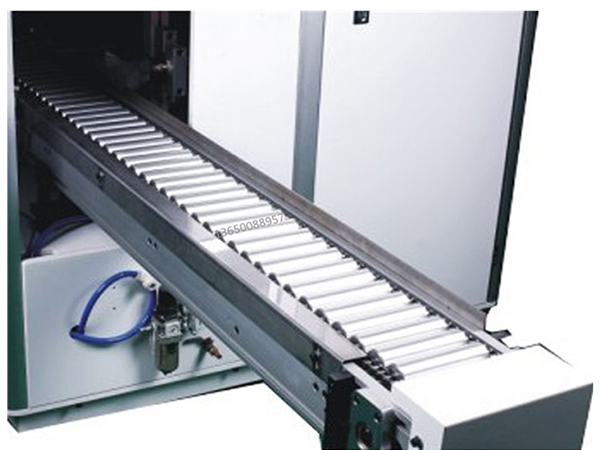

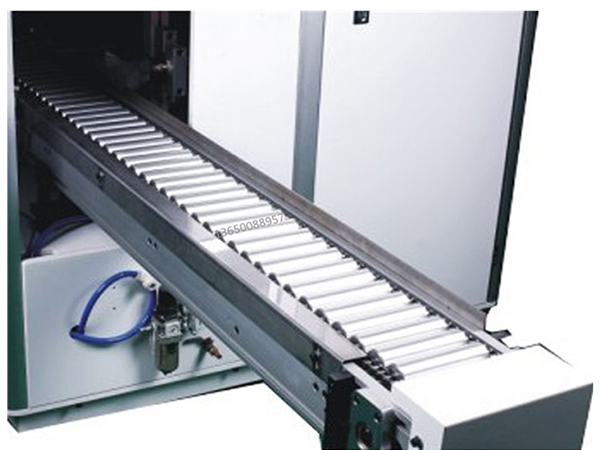

机器部位图片

产品图片

产品简介

专为圆形产品印刷而设计,主要适用于软管、瓶盖、离心管、膏霜罐的等圆形制品,并可实现部分制品的多色印刷及精确套色。

主传动采用欧洲名牌传动器材,辅以高速精密间隙分割器,实现部分精确分度传动,使整机运行平稳可靠,印刷速度高达3000-4800pcs/hr

整机控制采用国际名品PLC控制及设置简便快捷的触摸屏操作,轻易实现人机对话,操作更加得心应手。

油墨固化可采用电子式紫外线固化或红外线干燥,在保证性能稳定和节省电能的情况下,可获得更加优秀的固化效果。

具有离子风除尘、无件不印刷、气压过低报警、废料/错料等自动报警自动检测功能。

全自动上料系统与卸料机械手装置确保了印刷的连续与稳定,也尽可能避免了在印刷过程中造成承印物表面的刮伤,更加保障了作业员的安全操作。

根据客户要求,可选配以下配置

1、全自动上料器(可节省操作人员,实现全面自动化生产)

2、伺服+光标定位系统(可实现再次精确套色完成胶印、烫印)

3、机械定位装置(可实现多色套印)

4、丝印烫印相互转换功能

Product introduction

Specially designed for circular printing, mainly applicable to the hose, cap, centrifuge tube,

circular products cream cans, and can achieve accurate color and multi-color printing part products.

The main transmission adopts the European famous brand transmission equipment, supplemented

by high speed precision gap splitter, so as to achieve the accurate degree of transmission, make the

whole machine running more stable and reliable, printing speed can be as high as 3000-4800pcs/hr

Machine control using the international name PLC control and set up a simple and quick touch

screen operation, easy to achieve human-computer dialogue, the operation is more handy.

Ink curing can be cured by electronic UV or infrared drying, in the case of ensuring stable

performance and energy saving, can get a better curing effect.

With ion wind dust, no non printing, low pressure alarm, scrap / wrong material, such as automatic

alarm automatic detection function.

Automatic feeding system and unloading manipulator device to ensure the continuity and stability

of the printing, but also as far as possible to avoid the printing process caused the surface of the

substrate scratch, more to protect the safety of the operator.

According to customer requirements, optional with the following configuration

Automatic feeder (saving operation personnel, to achieve full automation of production)

Servo + cursor positioning system (which can achieve accurate color again complete offset printing, stamping)

Mechanical positioning device (can achieve multi-color)

Screen printing and transfer functions

技术参数(Specifications)

印刷尺寸范围(Printed Object Dimension) Φ:10mm-75mm L:20mm-230mm

电源要求(Power Supply) 380V 3Phase 50HZ 4.5Kw

气源要求(Air Supply) 6-8Bar

UV灯功率(UV lamp power) 2.4kw

速度(Speed) 2400-3000Pcs/hr

外形尺寸(dimension) 2500(L)x1700(W)x1900 (H)mm

总功率(Total Power) 4.5Kw

重量(Weight) 1500KG

|

设为首页

设为首页 加入收藏

加入收藏 联系我们

联系我们 您现在的位置:

您现在的位置: