二、技术性能 Technical performance

1、外形尺寸:(长×宽×高) 2700×500×1500(mm)

2、印刷范围:直径×长度(ф8ф18)×(70~180)mm还可根据用户要求另行设计制造不同规格的全自动丝印机。

3、印刷速度:35-50次/分钟。本机动力采用调速电机~220V),这种电机已配用我厂多种机型,该电机耐用、节能。

4、干燥箱温度调整范围:常温~100度。

5、连续印制:将待印产品置入料斗之后,经分支梳理、输送、印刷、干燥、风冷、收集等工序,便完成整个印刷流程。

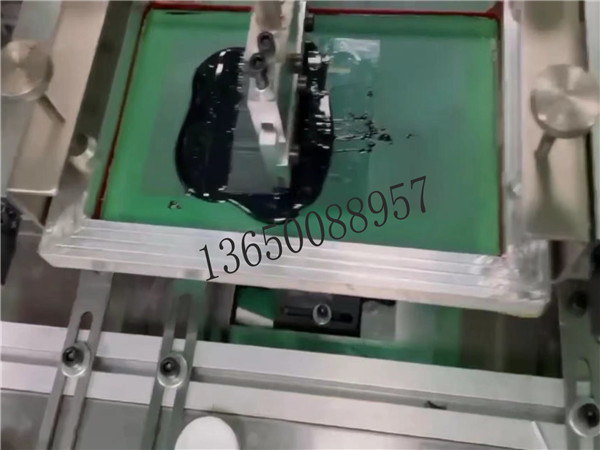

6、校对丝网版方便:本机设有网版对位微调装置,当网版初步固定在本机网版支撑框架内之后,由设定在机器上的左右、上下微调装置,将网版调校到印刷所需的最佳位置。

7、机械结构紧凑,机架采用标准型材制作,零部件经镀铬或热处理,提高了本机的稳定性和耐用度,延长了本机使用寿命。

1, overall dimension: (long × wide × high) 2700 × 500 × 1500 (mm)

2, printing range: Diameter × Length (ф8ф18) × (70~180) mm can also be separately designed and manufactured by fully automatic silk printing presses of different specifications according to user requirements.

3, printing speed: 35-50 times / min.Our power adopts speed regulating motor ~220V), which has been equipped with a variety of models in our factory, which is durable and energy efficient.

Temperature adjustment range of 4, drying box: 100 ° ~ at normal temperature.

5, continuous printing: After placing the products to be printed into the hopper, the whole printing process will be completed, after branch sorting, conveying, printing, drying, air cooling, collection and other processes.

6, proofreading screen version: the machine is equipped with the network version counter fine adjustment device. When the network version is initially fixed in the support frame of the local network version, the left and right and upper fine adjustment device set on the machine will adjust the network version to the best position required for printing.

7, mechanical structure is compact, the frame is made of standard profile, parts with chrome plating or heat treatment, improve the stability and durability of the machine, and prolong the machine service life.

三、印刷流程: Printing process:

料斗→梳理→输送→火焰处理→定位→印刷→干燥→收料

将待印的笔杆等承印物置入料斗,经过自动梳理装置梳理排列,以每次只送一支的准确数量向印刷部件输送承印物,印刷部件进行同步印刷,输送带向前同步进行输送承印后的笔杆到干燥箱进行干燥,让油墨冷却至常温后马上干燥,最后直接送产品入收集料斗并自行排列收集。整个过程都连续进行而完成全自动印刷流程。

Hopper → comb → delivery → flame handling → positioning → printing → dry → feed

Put the seal such as the pen rod to be printed into the hopper, sorted and arranged through the automatic sorting device, deliver the seal to the printing parts with only one branch at a time, the printing parts for synchronous printing, the conveyor belt forward synchronously transfer the pen rod to the drying box for drying, let the ink cool to normal temperature, and finally send the product into the collection hopper and collected by itself.The whole process is continuous and the fully automatic printing process is completed.

设为首页

设为首页 加入收藏

加入收藏 联系我们

联系我们 您现在的位置:

您现在的位置: