上料系统(Feeding system)

火焰处理(Flame treatment)

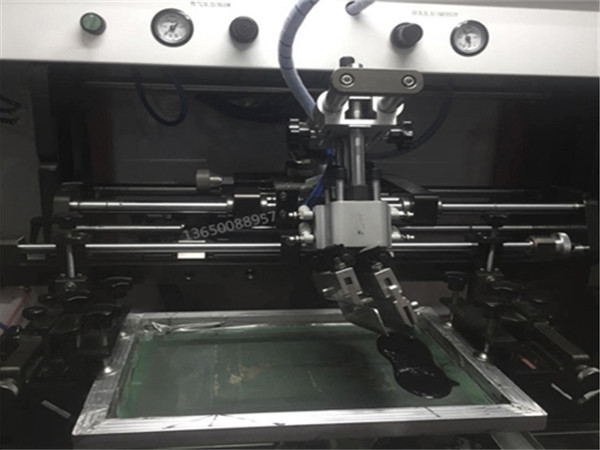

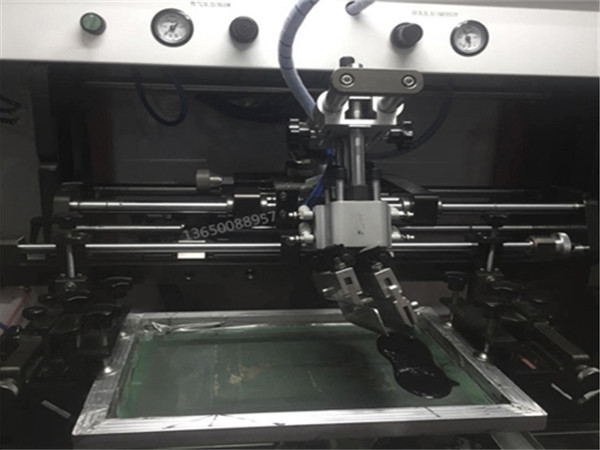

印刷系统(Printing system)

UV固化(UV curing)

下料(Material)

做过的产品图片(Picture of a product)

1色全自动丝印机技术参数及配置明细(One color automatic screen printing machine technical parameters and configuration details)

一、产品描述(IProduct description):

本机器能满足圆柱形、椭圆柱形和其他异形容器的圆弧面印刷需求,对塑胶、玻璃、金属等材质的容器均有兼容性。本机通过可编程控制器(PLC)与高性能的触摸屏(Touch Screen)实现对整机工作的智能性操控。以先进的进口马达、变速装置及机械传动组成全新高速的传动系统,实现无极变速、同步传送、自动对位、无瓶不印等控制功能。

The machine can meet the cylindrical, elliptical cylindrical and other special-shaped container arc printing requirements, plastic, glass, metal and other materials of containers are compatible. This machine realizes intelligent control of the whole machine through programmable controller (PLC) and high performance touch screen (Touch Screen) to realize the operation of the whole machine. The new high-speed transmission system is composed of advanced imported motor, transmission device and mechanical transmission, which can realize the control functions such as endless speed change, synchronous transmission, automatic alignment, no bottle and no printing.

二、主要功能(Main functions):

1、可供斜台上料输送带

2、上料自动调头功能

3、火焰表面处理系统

4、无级变速控制系统(变频器控制)

5、自动预先对位系统

6、无瓶不印刷系统(采用高性光电传感器, 透明瓶和黑色瓶都能可靠识别)

7、UV紫外线固化系统 HONOVIA(UV美国汉诺威)

1. material conveyor belt for inclined table

2.Automatic Adjusting Function of

3. Flame Surface Treatment System

4. CVT Control System (Frequency Converter Control)

5. Automatic Pre-positioning System

6. Bottle Free Printing System (with high performance photoelectric sensor, transparent bottle and black bottle can be reliably identified)

7.UV UV curing system HONOVIA (Hanover, UV USA)

三、主要配置(Main configuration):

1 机器主电机:SITI(意大利)

2 可编程控制器(PLC):OMRON(日本欧姆龙)

3 触摸屏:OMRON(日本欧姆龙)

4 光电开关:KEYENCE(日本基恩士/SICK(德国)

5 按钮开关:IDEC(日本和泉)

6 接触器: SCHNEIDER(施奈德)/FUJIFILM(日本富士)

7 继电器:OMRON(日本欧姆龙)

8 变频器:OMRON(日本欧姆龙)

9 紫外线固化系统:HONOVIA(美国汉诺威)

10 气动元件:SMC(日本)

1 Main motor: SITI( Italy)

2 Programmable Controller (PLC): OMRON (Omron, Japan)

3 Touch Screen: OMRON( Omron, Japan)

4 Light switch: KEYENCE (Keensh/Germany, SICK)

5 button switch: IDEC( Japan and Spring)

6 Contactor: SCHNEIDER( Schneider)/ FUJIFILM( Fuji, Japan)

7 Relay: OMRON( Omron, Japan)

8 Inverter: OMRON( Omron, Japan)

9 UV curing system: HONOVIA( Hanover, USA)

10 Pneumatic components: SMC( Japan)

四、技术参数(Technical parameters):

1 Circular printing diameter :ф15mm~ф100mm( based on actual product)

2 Round printing height :20 mm~270 mm

3 Diameter of flat printing: R20mm~R180mm

4 Print height :20 mm~270 mm

5 The fastest printing speed: when printing round products, the fastest printing speed is about 50-60 Pcs/ minutes, and when printing flat bottles, the fastest printing speed is 50-60 Pcs/ minutes

6 Electricity requirements: AC220V 1Phase/AC380V 3Phase 50Hz /60Hz

7 rated power: host 7.5 KW,

8 Pressure requirements :5~8 bar

9 Machine size: about L2700*W2000*H1700( subject to physical object)

10 Mechanical weight: about 1500 kg

|

设为首页

设为首页 加入收藏

加入收藏 联系我们

联系我们 您现在的位置:

您现在的位置: