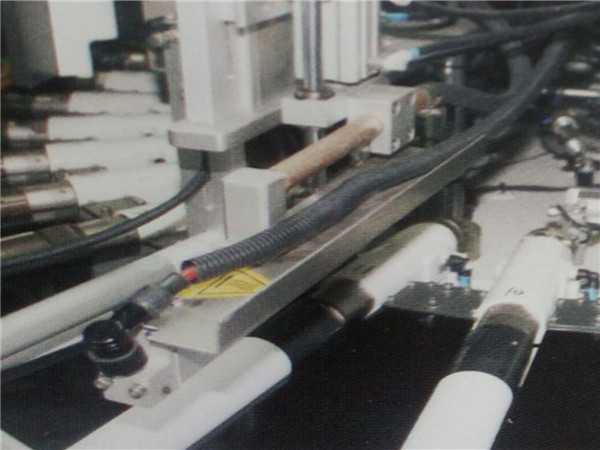

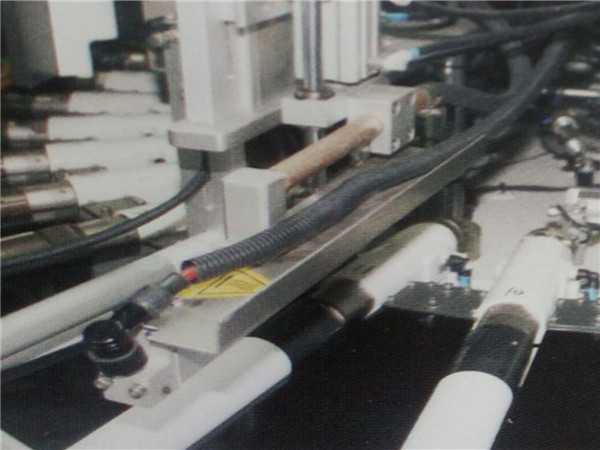

静电除尘与烧火装置 Electrostatic Dust Removal and Fire Burning Device

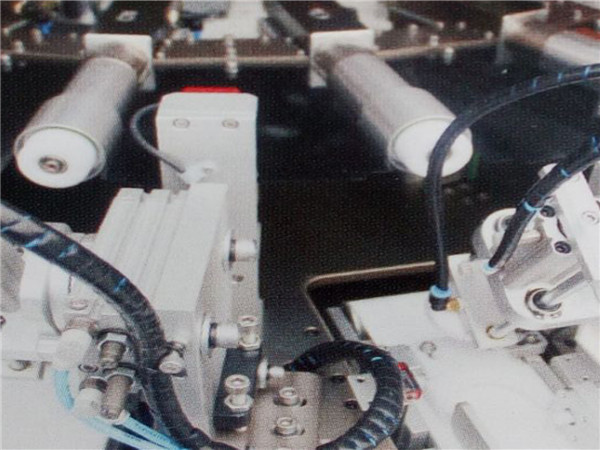

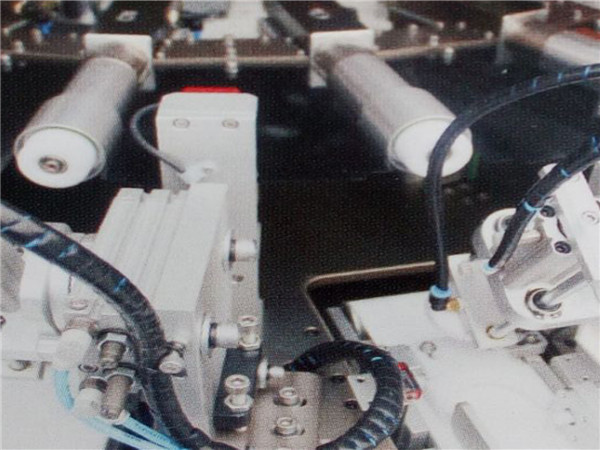

90°旋转上料 90° Rotary feeding

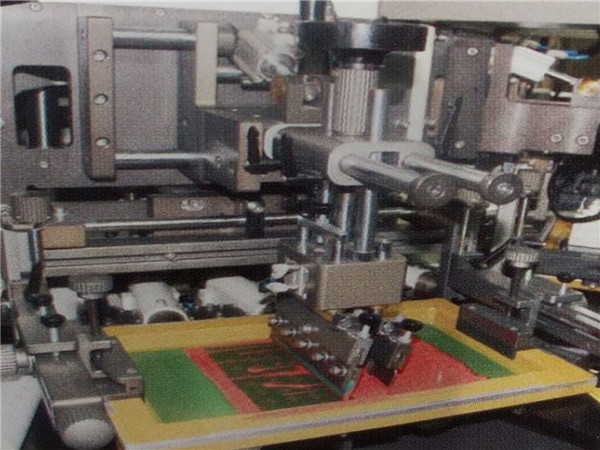

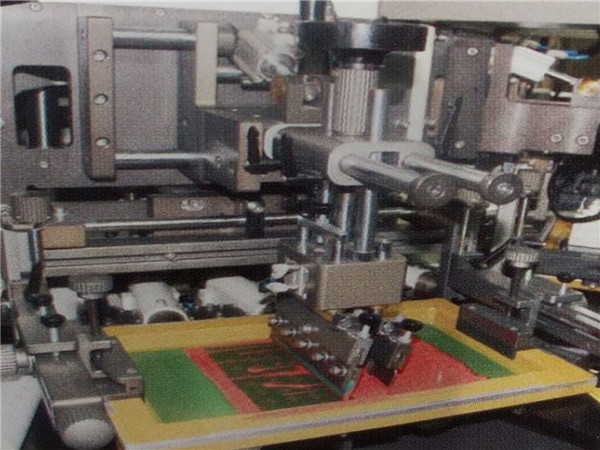

印刷系统 Printing system

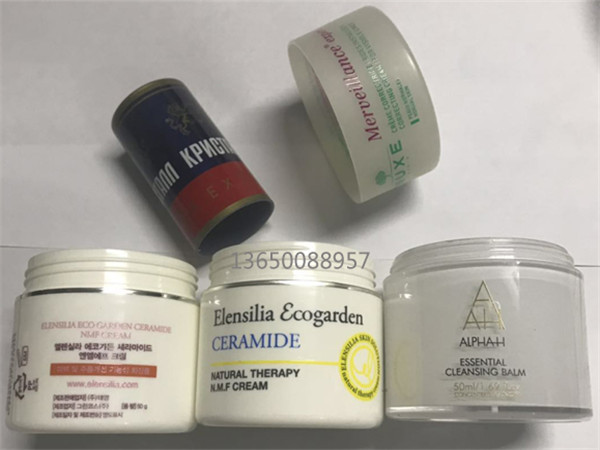

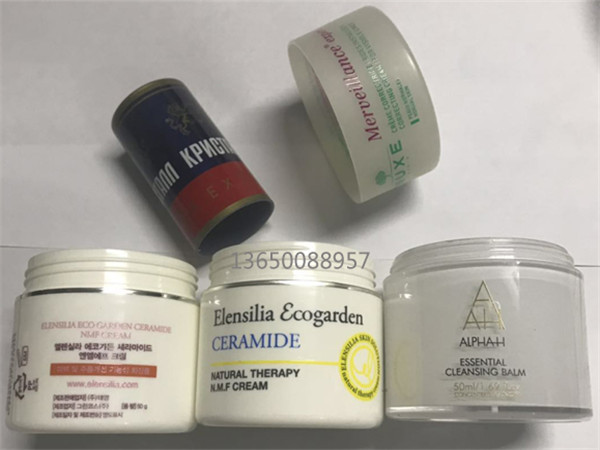

本机型为(3色全自动丝印机,适用于圆柱形产品 (软管,高霜罐)等UV 油墨, 采用德士高精密分割器,松下或欧姆龙PLC ,夹具伺服旋转,更换产品只需输入产品的直径即可,网板左右伺服,网板左右行程可调,光标伺服,质量稳定可靠,调试方便快捷.

This model is (3 color automatic silk printing machine, suitable for cylindrical products (hose, high frost tank)and other UV ink, using German high precision segmentation, panasonic or Omron PLC, fixture servo rotation, replace the product only input the diameter of the product, mesh board servo, mesh board left and right travel adjustable, cursor servo, quality is stable and reliable, convenient and quick debugging.

1.7寸触摸屏欧姆龙(日本)

2.欧姆龙PLC(日本)

3.转盘运转由德士分割器驱动(台湾)

4.印刷机构伺服控制。

5.刮墨回墨机构由配合滚珠丝杆(运行更平稳)(日本)

6.20轴管位座 ,紧密 NSK 轴承,进口硬轴组成。(日本)

7.主传动由意大利摩多利减速机配电机,欧姆龙变频器控制。(意大利与日本)

8.产品上下料动作运行更平稳准确。

9.本机的滚珠丝杆与导轨均采用日本 THK 品牌,精度更高,寿命更长。

10.本机 UV 灯箱的高度调节由电机驱动,布置更合理,员工的操作更简便,更安全。(美国)

11.本机具有独立真空系统,气动SMC对需要吸真空产品,保证独立的真空度使印刷品质更稳定。(日本SMC)

12.本机主要结构设计更合理,能实现 稳定高效生产。

13.伺服控制。

14.印刷定位机购由主电机传动,由凸轮驱动,完美与主机速度匹配, 不用单独调节.(气缸的要配合主机速度调节打出,缩回角度,由于气源影响,存在撞机的可能)

15.根据客户要求可选配上光油系统。

1. 7-inch Touch-screen of Omron (Japan)

2. Omron PLC (Japan)

3. The turntable operation is driven by the German splitter (Taiwan)

4. Servo-based control of the printing mechanism

5. The ink return mechanism consists with ball screw (smoother operation) (Japan)

6.20 Shaft pipe seat, tight NSK bearing, imported hard shaft composition (Japan)

7. The main drive is provided by Italian Moori reducer with motor and controlled by Omron converter (Italy and Japan)

8. The loading and unloading action of the product runs more smoothly and accurately

9. The ball silk rod and guide rail are both made of the Japanese THK brand, with higher accuracy and longer life.

10. The height adjustment of the local UV light box is driven by the motor, with more reasonable layout, easier operation and safer operation for employees (USA)

11. The machine has an independent vacuum system, the pneumatic SMC needs to vacuum suction products, to ensure that the independent vacuum degree to make the printing quality more stable. (Japan,SMC)

12. The main structure design of the machine is more reasonable, and it can achieve stable and efficient production.

13. Servo control

14. The printing positioning machine is driven by the main motor and driven by the cam, which perfectly matches the speed of the main engine without adjusting separately. (The cylinder should be matched with the host speed adjustment, retracted Angle, and the possibility of collider due to the influence of gas source)

15. Optical oil system can be selected according to customer requirements

设备概述: 人工把产品放到输送带上--自动上料--静电处理--火焰处理--光标定位--印刷一色--UV--转盘旋转--印刷二色--UV--转盘旋转--印刷三色--UV--转盘旋转--自动下料。工作状态为全自动。

Equipment overview: manually put the product on the conveyor belt- -automatic feeding- -static treatment- -flame treatment- -cursor positioning- -printing monocolor- -UV- -rotary rotation- -printing two color- -UV- - -rotary rotation- -printing three color- - -UV- -rotary rotation- -automatic feeding. Operating status is fully automatic.

技术参数

technical parameters

|

印刷颜色Print color

Printing Colour

|

3 色丝印

3 Color Screen Printing

|

|

单周期monocycle

Single period

|

Yes

Yes

|

|

连续模式Continuous mode

Continuous mode

|

Yes

Yes

|

|

项目记数Project count

Item Count

|

Yes

Yes

|

|

印刷速度调节Printing speed adjustment

Printing speed control

|

Yes

Yes

|

|

各部位延时Each part of the delay

Time delay of all parts

|

Yes

Yes

|

|

印刷速度print speed

Printing speed

|

2700-3000pcs/hour

2700-3000pcs/hour

|

|

最大印刷面积Maximum print area

|

直径 19-60MM

Diameter 19-60 mm

|

|

刮刀左右行程Left and right stroke of scraper

|

200

|

|

刮刀,回油刀上下行程Scraper, return to the oil knife up and down the travel

Scraper, RETURN OIL KNIFE UP AND DOWN STROKE

|

气缸控制 20mm,可调丝杆行程 50mm

Cylinder control 20mm, adjustable screw stroke 50mm

|

|

主马达驱动Main motor drive

|

变频电机Variable frequency motor

|

|

控制系统 Control System

|

欧姆龙 PLC Omron Plc.

|

|

控制电路电压Control Circuit Voltage

|

24VDC

|

|

电源电压Supply Voltage

|

380V~50HZ

380V ~ 50HZ

|

|

总功率Total power

|

15KW

18KW

|

|

气源要求Air Source Requirement

|

5~6BAR

5 ~ 6 bar

|

|

设为首页

设为首页 加入收藏

加入收藏 联系我们

联系我们 您现在的位置:

您现在的位置: